Feel free to contact us now

Estimate Form

Non Destructive Testing Experts: Protecting Your Commercial Property With Precision

At East Coast Industries, Inc., we know that beneath the surface, your commercial property's strength and dependability rest. Focusing on non destructive testing (NDT), we assist businesses in New York City and New Jersey, as well as customers around the country, in uncovering latent defects and possible breakdowns without sacrificing the integrity of your infrastructure. Modern technologies combined with decades of experience allow us to provide exact, data-driven insights that maintain the safe and effective operation of your systems. Whether you're managing industrial facilities, high-rise buildings, schools, or data centers, our services are designed to protect your assets and minimize costly downtime.

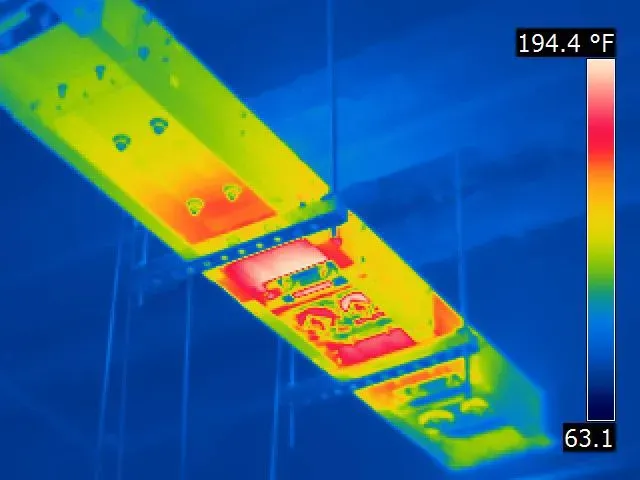

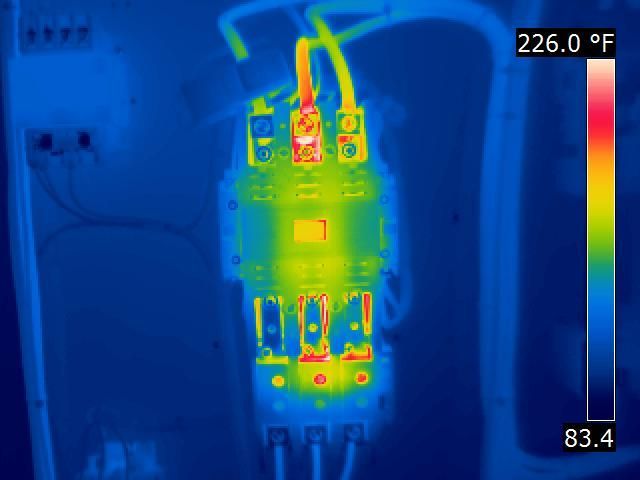

Non destructive testing (NDT) is an advanced inspection method used to identify internal flaws and weaknesses in materials, systems, and equipment. ECI employs various technologies, including ultrasonic testing, infrared thermography, vibration analysis, steam trap testing, and power monitoring, to detect anomalies that would otherwise remain hidden. This proactive preventative maintenance approach prevents minor issues from escalating into major problems.

With modern technologies and sophisticated approaches, East Coast Industries, Inc. keeps ahead of the curve. Our ultrasonic pipe and tank testing, for example, can find concealed corrosion; infrared testing discovers electrical flaws, and steam trap testing reveals energy inefficiencies. With our exact, data-driven approach, we have effectively helped commercial clients throughout NYC and NJ extend the lifetime of their equipment and lower repair costs.

Accuracy and experience are important for protecting your investment. Count on East Coast Industries, Inc. to provide the best degree of NDT testing solutions catered to the particular requirements of your facility.

Get in touch

right now to arrange a visit and learn how we can protect your infrastructure.

Decades of Expertise, Unmatched Precision

We have a proven track record of detecting issues early, preventing costly repairs, and ensuring structural integrity. When you choose us, you’re choosing expertise, reliability, and a commitment to safety.

40+

Established in 1983

Over 40 years of industry leadership

100+

Years of Combined Experience

Skilled & certified technicians

9400+

Tests Completed

Proven track record of precision and reliability

"Trusted by Engineers. Proven in the Field."

Stay Ahead Of Equipment Failures With Our Non Destructive Inspection Expertise

At East Coast Industries, Inc., we envision protecting your commercial property, beginning with things you cannot see. Our expertise in non destructive inspection (NDI) enables us to identify defects in your infrastructure while preserving its integrity. This proactive approach helps you avoid costly repairs and unexpected failures. By combining advanced technology with a team of experts, we deliver accurate and dependable data to keep your systems functioning optimally and your company running smoothly.

Modern technologies such as ultrasonic testing, infrared thermography, and vibration analysis are employed in non destructive inspections to evaluate rotating equipment, structural components, electrical systems, pipes, and tanks. Our approach delivers reliable, real-time data that enables preventive maintenance and timely repairs by detecting corrosion, loose electrical connections, and failing bearings, without compromising the integrity of the materials being inspected.

This strategy is especially important for industries such as infrastructure, manufacturing, and energy facilities, which operate under challenging conditions where even small failures can lead to significant downtime and financial losses.

The true value of non-destructive inspections lies in early identification and prevention. Identifying issues early allows clients to prevent unexpected shutdowns, extend the life of critical equipment, and maintain compliance with safety regulations.

Our team of skilled experts combines the latest technology with extensive experience to deliver accurate, practical results that keep your business ahead. Our goal at East Coast Industries, Inc. is to safeguard your investment and guarantee the effectiveness and safety of your operations. If you are ready to capitalize on the advantages of our non destructive examinations, get in touch with us right now to find out how our knowledge might help your facility.

East Coast Industries Inc.

SERVICES WE PROVIDE

Professional Non-Destructive Inspection Solutions That Keep Your Commercial Property Safe And Efficient

Non-destructive inspections revolutionize the way that commercial property structural integrity and safety are maintained. Our specialty at East Coast Industries, Inc. is offering clients innovative NDT services. With decades of expertise and modern technologies, we enable companies to find hidden flaws and weaknesses without interfering with business operations or compromising important infrastructure.

Modern non-destructive inspection services leverage ultrasonic testing, infrared thermography, and vibration analysis to enhance our inspection procedures. These advanced techniques allow us to identify internal defects, corrosion, electrical anomalies, and material fatigue with precision.

We specialize in evaluating critical components such as structural steel, tanks, pipes, electrical systems, and rotating equipment. Our tailored approach ensures comprehensive and accurate assessments, particularly vital for high-rise buildings and industrial facilities, where even minor flaws can lead to significant downtime and financial losses.

Our knowledgeable staff provides detailed inspections and clear, meticulous reports to property managers, chief engineers, and facility managers, empowering them to make informed maintenance and repair decisions. This proactive approach extends the life of your assets and minimizes costly downtime.

East Coast Industries, Inc. is listed as one of the most reputable NDT companies that provides an excellent, smooth inspection experience with unparalleled accuracy and professionalism, and the best reporting of all NDT New Jersey

businesses. Get in touch with us right now to find out more about our creative

NDT NYC

inspection solutions if you are eager to safeguard your commercial property and stop unplanned failures.

Ensure Safety with Precision Testing

Our precise, non-intrusive inspections help you detect issues early, ensuring safety, compliance, and long-term durability. Schedule your assessment today!

We Maximize Accuracy And Efficiency With Our Advanced Nondestructive Testing Equipment

At East Coast Industries, Inc., we are aware that nondestructive testing equipment are defined by their accuracy and dependability. We have developed our name by using innovative, non-destructive testing tools that are not only modern but also specifically fit for the special needs of commercial infrastructure. Using our sophisticated instruments and knowledgeable staff, we enable customers to identify internal defects and possible failures without endangering valuable assets.

Our nondestructive testing equipment incorporates several sophisticated technologies, including ultrasonic testing equipment, infrared thermography cameras, and vibration analyzers. Specifically, infrared (IR) cameras can identify electrical hot spots and energy inefficiencies, ultrasonic equipment measures material thickness and detects malfunctioning steam traps, and vibration analysis identifies mechanical problems like misalignment and bearing wear. These instruments provide precise, real-time data across the lifespan of critical infrastructure, which allows for effective preventative maintenance.

However, technology by itself cannot be sufficient. The success of nondestructive testing methods mostly relies on the knowledge of the specialists running the equipment. Our team of qualified experts are trained to evaluate data, interpret findings, and spot possible hazards endangering the efficiency and safety of your commercial facility.

We also keep ahead of industry developments by always changing our tools and methods to satisfy changing safety rules and industry standards.

At East Coast Industries, Inc., we provide accurate and useful results by combining modern nondestructive testing tools with expert knowledge. Get in touch with us right now to find out more

about

our creative ideas if you are ready to safeguard your business and stop expensive downtime.

Industries We Serve

- Commercial Buildings

- Residential Buildings

- Hospitals

- Data Centers

- Manufacturing Facilities

- Cruise Ships

- Factories

- Any type of operation that has electrical based equipment.

Your Infrastructure Deserves The Best – Trust Our Predictive Maintenance Services

Imagine being able to identify equipment breakdowns before they begin, therefore avoiding expensive repairs and downtime. With our predictive maintenance services, meant to keep commercial buildings running at maximum performance, East Coast Industries, Inc. makes that a reality. Employing sophisticated technology and data-driven approaches, we enable customers to maximize safety and efficiency while extending the lifetime of their vital infrastructure.

Modern non destructive testing (NDT) techniques—including ultrasonic testing, infrared thermography (IR), vibration analysis, and power monitoring—form the basis for our predictive maintenance services. These instruments let us find early, otherwise invisible, indicators of structural weakening, corrosion, and wear. Constant collecting and analysis of performance data helps us to forecast component failure and intervene early to prevent failures. Along with minimizing unplanned downtime, this method maximizes energy use and cuts repair expenses.

East Coast Industries, Inc. understands the unique infrastructure challenges from New York City to South Jersey, setting us apart from other predictive maintenance companies. From industrial plants and high-rise buildings to retail spaces, we provide specialized maintenance plans fit for your particular requirements. Our knowledgeable staff offers comprehensive inspections and detailed reports that let you make wise decisions and maintain the uninterrupted operation of your systems.

East Coast Industries, Inc., one of the top predictive maintenance firms, is dedicated to providing first-rate service, maximizing operational efficiency, and safeguarding your assets. We take great satisfaction in providing customized solutions to assist you in preventing unanticipated breakdowns, lowering maintenance expenses, and maintaining seamless operations. Our knowledge and modern technologies let you concentrate on running your company while we take care of infrastructure health recommendations. Do not wait until little problems become big ones; get in touch with us now to find out how our creative ideas might protect your business property and improve your profitability.

PRIMARY SERVICE AREA

New York City, New Jersey and The Surrounding Tri-State Area

Established customers In:

Proven Non-Destructive Testing Solutions to Keep Your Systems Running Smoothly

At East Coast Industries, Inc., non-destructive testing (NDT) is about preserving the integrity of your commercial property and ensuring safety and efficiency; it is more than just finding issues. For decades, we have been the dependable brand in nondestructive testing methods. Our expertise helps you to avoid costly repairs and downtime by allowing us to identify structural defects and internal issues without endangering your vital systems.

Having worked in New York City and New Jersey, we are conscious of the specific challenges posed by the various infrastructures of the regions. We have dealt with customers in many different industries from high-rise buildings and industrial plants to power generation facilities and commercial complexes to generate precise, reliable, and quick results. Our local knowledge, together with national experience, helps us to tailor our services to meet the specific needs of every institution while still adhering to industry standards and local safety regulations.

Our distinction is our dedication to safety, dependability, efficiency, and accuracy. We find problems early and offer data-driven insights for preventative maintenance by using creative technologies such ultrasonic testing, infrared thermography, vibration analysis, and power monitoring. This allows our customers to increase the dependability of their infrastructure and reduce energy waste while increasing operational efficiency and environmental responsibility.

East Coast Industries, Inc. excels not only at identifying potential issues but also at preventing them. Our advanced, non-destructive testing methods provide you with the assurance to manage your company with minimal risk and maximum efficiency. Our creative solutions, experienced staff, and commitment to excellence assist you to protect your assets and avoid costly and unexpected failures.

Contact us right now to witness the East Coast Industries difference and find out how we can keep your infrastructure operating at its best.

Certifications